Vision industrielle

Machine optical inspection vision

-

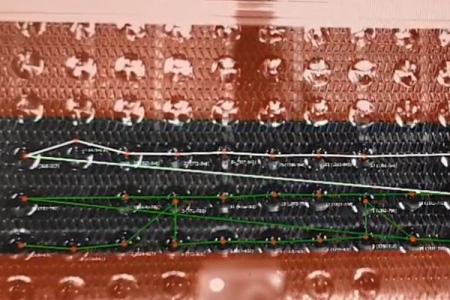

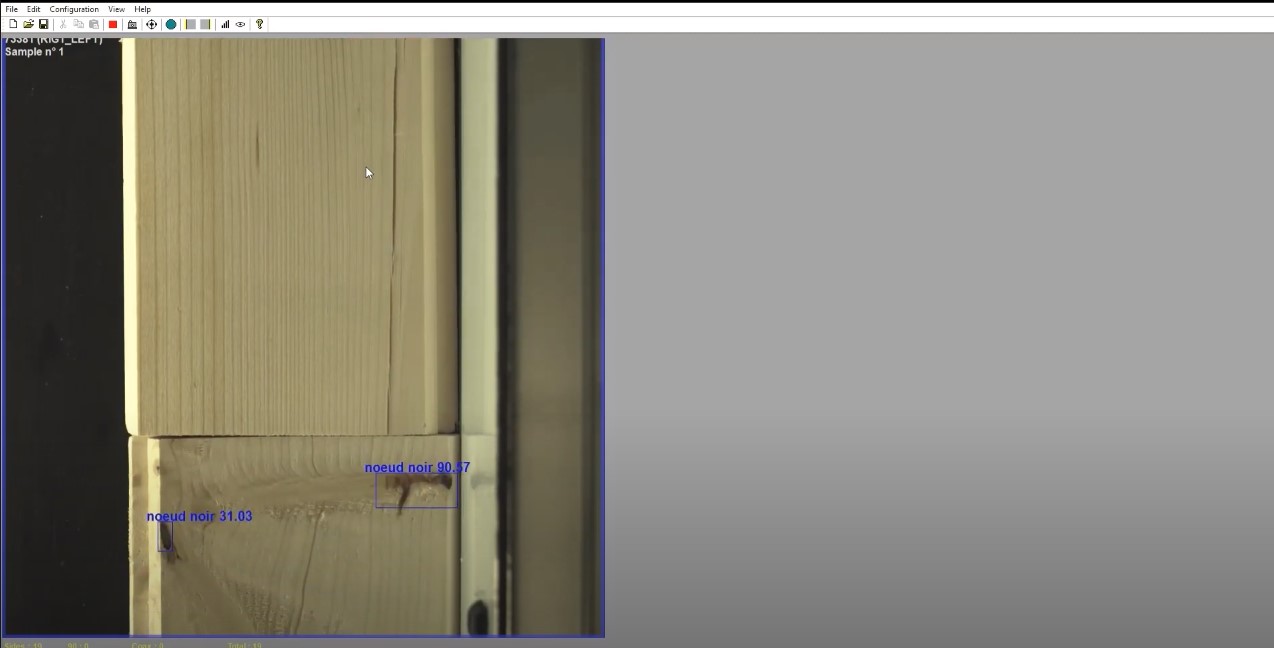

Classification : Complex defects detection, classification and sorting

-

Detection : 2D positions of moving objects search

Detection : 2D positions of moving objects search -

Reading : Complex character strings and OCR replay

- Classification : Complex defects detection, classification and sorting

- Detection : 2D positions of moving objects search

- Reading : Complex character strings and OCR replay

Logiciel de vision industrielle

The Deep Capture strengths

Our machine vision software uses deep-learning, a new technology making it one of the most efficient and adaptable tools on the market.

Artificial intelligence

Through deep learning our software Deep Capture allows a detection generalization from a supervised learning. In other words, it can detect items with different aspects, shapes and sizes from what it has learned. The system is, for example, very interesting for detecting objects subject to interpretation.

Realtime analysis

Our machine vision software enables near real-time detection. We can achieve a framerate at around 60 fps per camera. This high framerate allows us to obtain multiple detection results for a single object even under high speed scenarios. Coupled with decision support algorithms, this characteristic gives our software great confidence in the quality of its prediction.

Best performance

The performance of a system is measured on two axes: the true positives detection rate (faults, objects to be identified) and the false positives rate (false rejections). With Deep Capture, we guarantee you get the best compromise between these two rates.

Simple et intuitif

Avec le logiciel de vision industrielle en deep learning Deep Capture, les temps de changements de campagne mécanique et soft sont quasi inexistants. De plus, le système est insensible aux variations d’éclairage et ne nécessite donc pas de configuration spécifique à ce niveau. Notre outil nouvelle génération de vision industrielle est très simple d’utilisation et ne requiert aucune compétence particulière en deep learning.

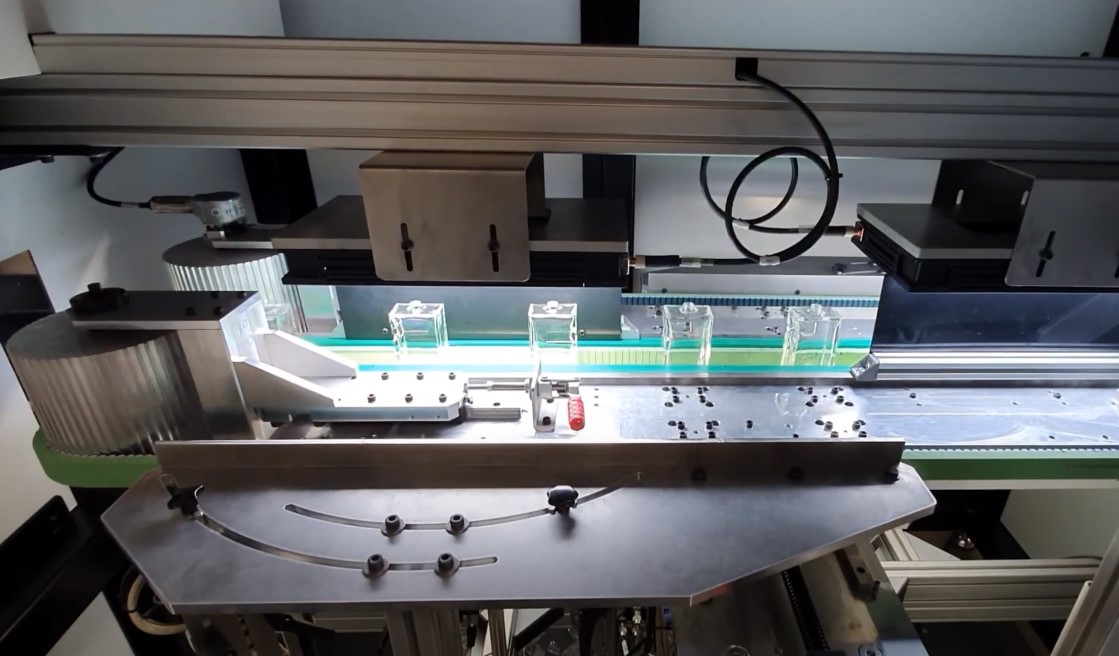

Clés en main

Nos ingénieurs spécialisés en vision industrielle s’occupent des différentes phases de développement, du logiciel. De la labellisation des photos au paramétrage du réseau de neurones jusqu’à l’intégration sur site du système, l'équipe Deep Capture est à vos côtés. Nous possédons aussi les compétences : mécanique, électrique et automatisme permettant la conception de la machine dans son ensemble.

La vision industrielle en deep learning

Deep Capture, le logiciel, comment ça marche ?

Pour mieux comprendre la vision industrielle en deep learning, visionnez notre courte vidéo explicative du fonctionnement de notre logiciel Deep Capture !

Learn more about Deep Capture, machine vision software

Deep learning, what is it? Why is it more efficient in machine vision?

Qu’est-ce que c’est ? Pourquoi c’est plus performant ?

Deep learning is a set of techniques based on so-called “artificial” neural networks. The underlying paradigm is revolutionizing the way of designing applications, especially in machine vision field. We have moved from developing deterministic models validated by a set of business data and experts to developing the non-deterministic model which teaches how to solve problems addressed to it from a large number of business data and successive tests. The gain produced by the use of these techniques is the ability for the model to learn to recognize invisible or unconscious characteristics for the developer that it would therefore not or hardly have been able to integrate into a classical model.

The very construction of these neural networks allowsthe model to adapt to recognizing items for which it has not been specifically trained. This characteristic allows deep learning to be an essential machine vision tool for finding various faults in a controlled production environment.

La vision industrielle en deep learning

Applications in Machine Vision

Whatever the business sector, the implementation of our Deep Capture machine vision software is very simple and intuitive.

About us

Based in the Nantes region, the Deep Capture team is a subsidiary of CIM ATLANTIQUE, an electromechanical engineering company specializing in the design of machines and robots.

Our team consists of passionate computer scientists and engineers specializing in artificial intelligence. Our engineers have very different skills from those of a visual engineer working in “conventional” algorithms thanks to their dual skills in optics and deep learning.

We are integrated in all trades (mechanical design, electrical, automation), we are therefore able to provide a solution and a turnkey sorting machine for each of your projects.

Une question sur la vision industrielle en deep learning

Contact Us

You can use the following form for any information on our machine vision products and services.

We will get back to you as soon as possible.